Introduction

In the dynamic landscape of modern workplaces, where technological advancements are the driving force behind productivity, ensuring the safety of electronic components is paramount. Electrostatic discharge (ESD) poses a significant threat to sensitive equipment, potentially causing irreparable damage. To combat this, companies turn to specialized solutions, and one such key player in this realm is the ESD table.

Understanding Electrostatic Discharge (ESD): A Hidden Menace

Before delving into the significance of an ESD table, it’s crucial to comprehend the menace it addresses – electrostatic discharge. ESD is the sudden flow of electricity between two electrically charged objects. In the context of workplaces, this discharge can wreak havoc on electronic components, particularly in manufacturing environments where sensitive devices and components are prevalent.

Imagine a scenario where a technician, unknowingly charged with static electricity, handles a delicate electronic circuit. The discharge, though imperceptible to the human senses, can lead to catastrophic consequences for the equipment. It’s akin to a silent assassin, striking without warning and leaving a trail of damage in its wake.

The Role of ESD Tables

The design of an ESD table goes beyond its surface. It encompasses a comprehensive approach to create a work environment that safeguards electronic components throughout the entire manufacturing or testing process. From the choice of materials to the grounding mechanisms, every element is meticulously considered to ensure optimum protection.

ESD Table Design: Comprehensive Protection

The design of an Electrostatic Discharge (ESD) table goes beyond its surface, aiming to create a protective work environment for electronic components. Materials like antistatic laminate are chosen to prevent triboelectric charging. Grounding mechanisms, such as straps, ensure the safe discharge of static charge. ESD tables embrace modularity, catering to diverse workplace needs. They feature customizable elements like shelves and drawers, enhancing versatility for different workflows. Every aspect, from material selection to modularity, is meticulously crafted to provide optimum protection throughout the manufacturing or testing process, making ESD tables essential for safeguarding sensitive electronic equipment.

Unleashing the Power of ESD Tables in the Workplace

ESD tables wield significant influence in the workplace, offering a range of advantages to bolster electronic component integrity and cultivate an optimal work environment. First and foremost, they elevate productivity by safeguarding components from electrostatic discharge, empowering technicians to work confidently and attentively. This assurance translates into heightened efficiency, fostering a work culture free from the constant concern of unintentional damage to sensitive equipment.

Additionally, ESD tables deliver substantial cost savings by acting as a preventive measure against ESD-related damage, sparing companies from the financial burdens associated with repairs, replacements, and production delays.a

Moreover, their implementation ensures compliance with rigorous industry standards, positioning businesses as responsible and reliable players in sectors where quality and safety are paramount.

Lastly, ESD tables contribute to the longevity of electronic components, protecting them from premature failure and sustaining the seamless operation of devices and systems across various industries.

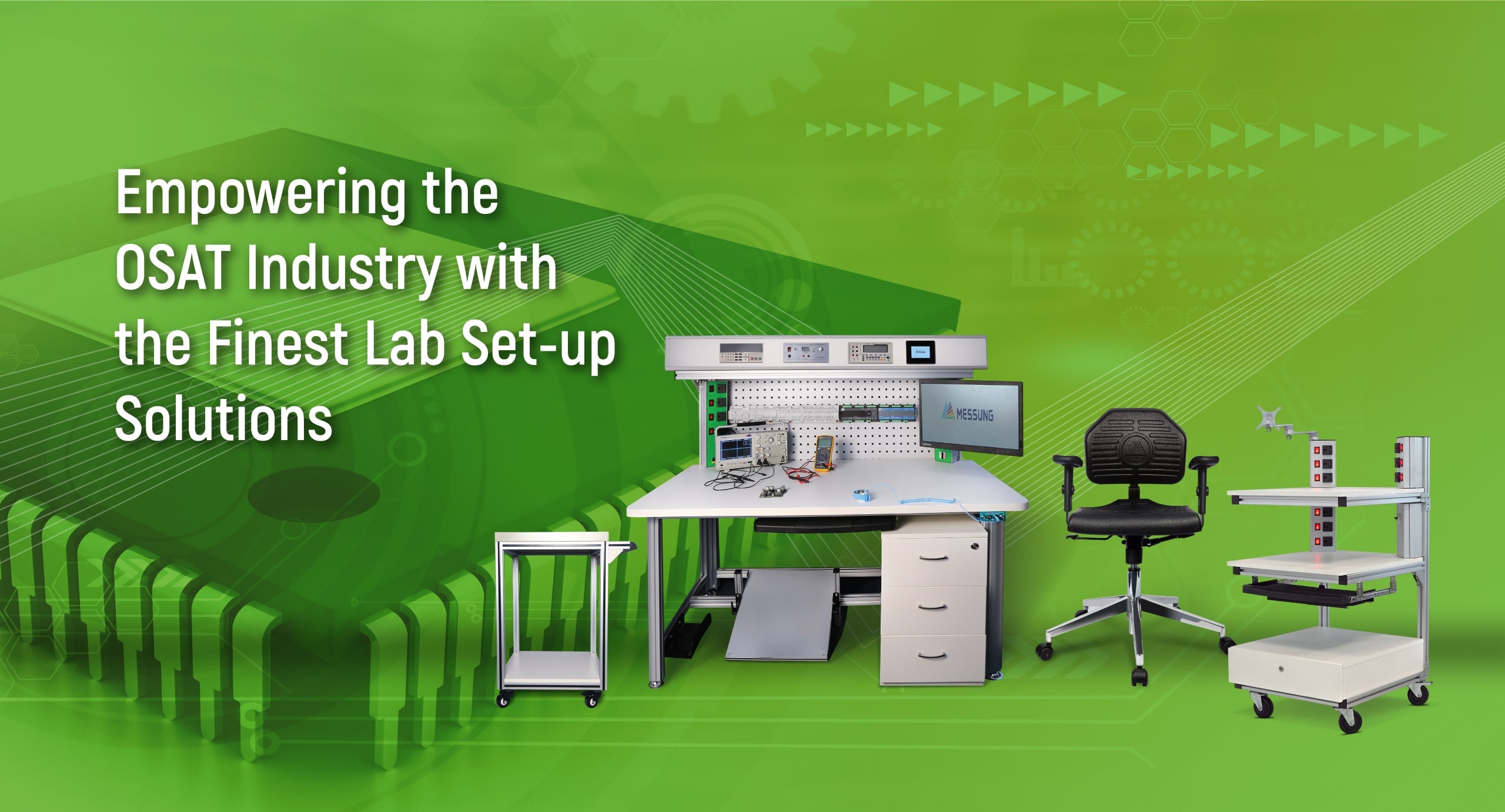

What Messung Workplace Technology Offers?

Messung Workplace Technology provides top-tier ESD tables designed to prevent electrostatic discharge (ESD) failures effectively. These tables boast a unique volumetric conductivity achieved through the incorporation of carbon particles throughout the entire volume. Unlike tables with a single conductive layer, Messung’s ESD tables disperse static charges uniformly, minimizing the risk of ESD failures.

The volume conductive layer connects seamlessly to the table’s base structure, facilitating the dissipation of static charges into the ground without requiring external grounding. This innovative design ensures negligible ESD failures, as the charge dissipates over a broad area, resulting in weak static strength and prolonging the overall ESD system’s lifespan.

Additionally, Messung’s ESD tables maintain their protective properties even in the presence of chipping, cutouts, or grommet holes. The volumetric ESD acts as a consistent conductive layer throughout the entire wood, guaranteeing that static charges dissipate through infused carbon particles, thereby eliminating any risk of ESD failures. In essence, Messung Workplace Technology offers ESD tables of the highest quality, prioritizing reliability and longevity in ESD protection.

Conclusion: Safeguarding the Future of Electronics

In the fast-paced world of technological innovation, the importance of ESD protection cannot be overstated. As workplaces continue to evolve and become more reliant on sophisticated electronic equipment, the role of ESD tables becomes increasingly crucial.

Investing in ESD tables is not just a practical choice; it’s a strategic decision that pays dividends in the form of protected equipment, enhanced productivity, and a secure foundation for future technological advancements.